Quotation For Coconut Shisha Charcoal

The price of Coconut Shisha Charcoal could be varied based on market’s fluctuation, so the price will depend on the following factors: the quantity, the type, the quality, the packaging … of the order.

It would be a much better price if we could discuss with you in advance for exploring your demand, so that we would offer our best price for each kind of products and delivery terms.

Contact Info of ECC

- Toan Nguyen – CEO

- Phone/Zalo: 0985 336 248

- Whatsapp/Viber: +84 985 336 248 (English & Vietnamese)

- Email: toannd@ecc-vn.com

- Office: 8FL, Building No 10/63 O Dong Lam Street, Dong Da District, Hanoi, Vietnam.

Some Quality Indexes of our Coconut Shisha Charcoal

| Indexes | Description |

| Ash Content | 2.0% – 2.5% |

| Burning Time | 2 hours + |

| Ignition Time | 10 minutes |

| Odor | Free |

| Ash Color | Natural White / Grey |

| Fix Carbon Content | 75% – 80% |

| Moisture | 5% – 8% Maximum |

| Volatile Matter | 15% – 18% |

| Calorific Value | 7,500 – 8,000 Kcal |

What is coconut shell charcoal?

Coconut shell charcoal or coconut charcoal is a product made from dried coconut shells specifically used for burning to provide heat or used in cooking food. This is a popular product used for cooking food, especially hot pot restaurants and BBQ grills.

Coconut shell is the remaining raw material of the coconut after removing the inner meat and outer coconut shell. Since ancient times, coconut shells have been used by people to make water ladles, rice bowls, handicraft products… However, due to the large amount of excess coconut shells, if left in the environment, it will cause waste. costs and environmental impact.

In particular, coconut shell charcoal does not contain toxic chemicals so it is very safe for health. Furthermore, the price is much cheaper than other types of charcoal because they are grown a lot in Ben Tre.

Advantages of coconut shell charcoal

- Safe for the environment and friendly to consumers’ health thanks to natural coconut shell materials.

- High heat, even fire, no odor, no dust

- Contains no preservatives or fire stimulants

- Easy to ignite, quick to ignite, no burning smell when burning and no eye irritation

- Long, durable burning time helps save costs, very suitable for use in Hot Pot and Grill restaurants. Especially smokeless grill or BBQ restaurants.

Standard coconut shell charcoal production process

Choose coconut shell ingredients:

Usually the selected material must be old, dry coconut shells with high hardness and moisture below 15%, which will help the charcoal structure to be hard, not crumble, and have less soot in the following stages.

Heating coconut shells in the oven:

- After being selected, the raw materials will be put into the furnace under oxygen-deficient conditions at a temperature of about 500 degrees Celsius.

- Due to the firing in the absence of oxygen, the combustion process is incomplete, eliminating the water vapor, leaving only the black carbon with high hardness and good burning ability. The product obtained after this process is coconut shell charcoal.

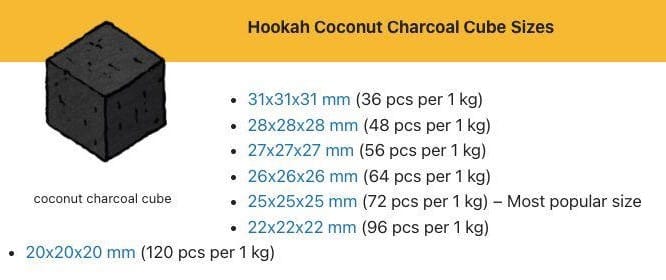

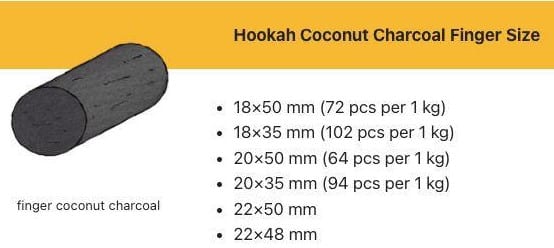

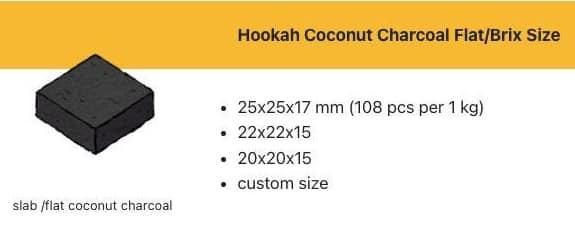

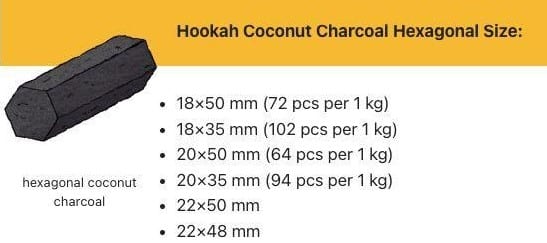

Shape and size of coconut shell charcoal

Because during the heating process, coconut shells can be broken into many different large and small pieces, so when the heating process ends, the finished charcoal will be sifted into many different sizes. Depending on the intended use, the manufacturer will shape it to suit the following sizes:

- Coconut shell charcoal pieces come in the following sizes: 2×6, 3×6, 4×8, 6×12, 8×20 mesh

- Coconut shell charcoal is in cylindrical tablet form

- Powdered coconut shell charcoal is smooth and soft

- Types used in cooking and baking food come in the form of tubes, rectangular bars, square pellets, etc.

Process of producing shisha charcoal from coconut shell charcoal

Coconut shell → Carbonization furnace → Coconut shell charcoal → Fine grinding, adding active ingredients → Pressing into pellets → Drying → Packaging.

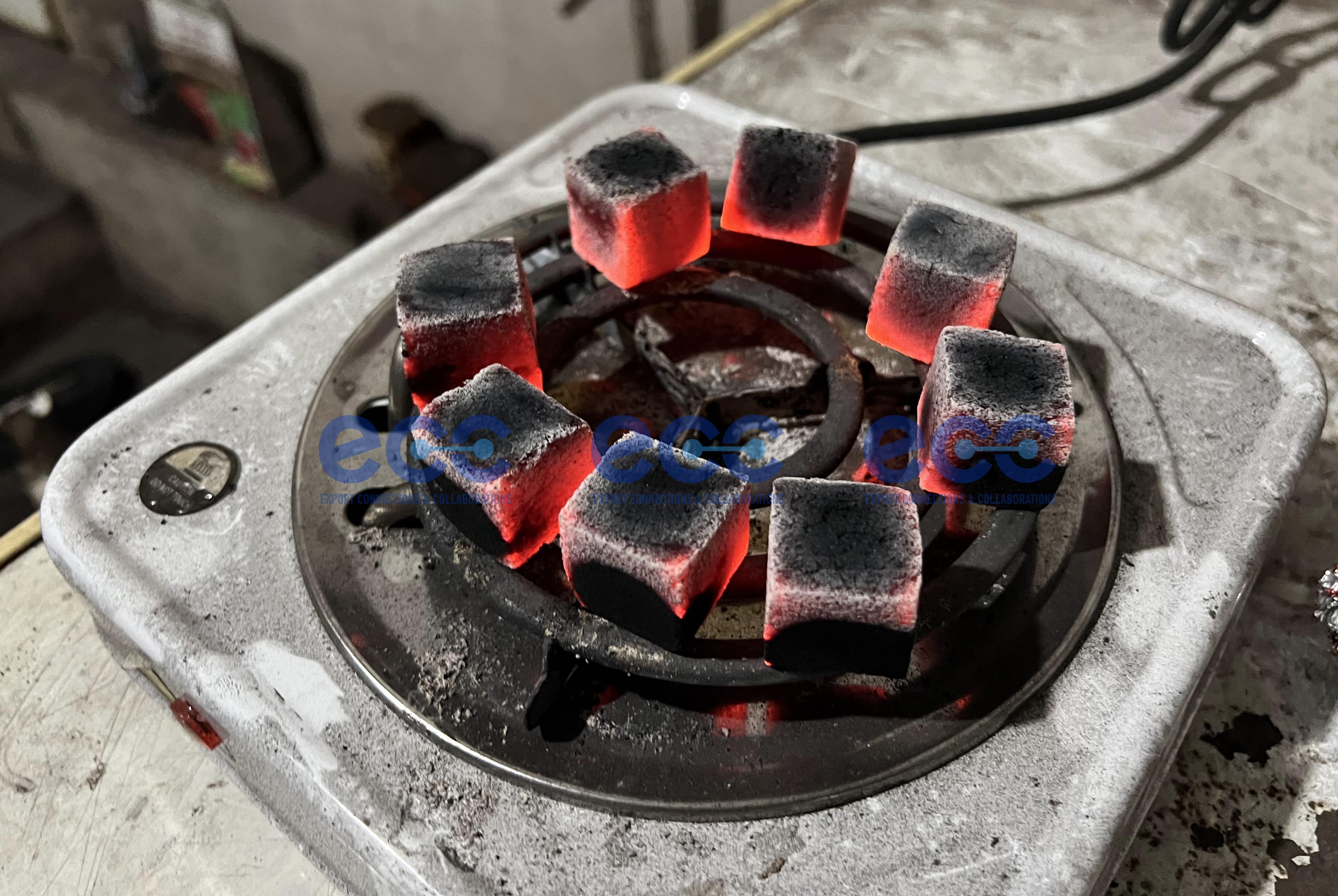

Please find below photos of our manufacturing process, materials, machinery and products as well as our business loading: